Description

ESD Bench Matting – The surface layer is static dissipative and resistant to abrasion, heat and solder splash. The black bottom layer is conductive giving a typical resistance to ground 10ˆ6 – 10ˆ8. The texture can easily be cleaned with our mat and table top cleaner. The user can be easily grounded to the mat with an 10mm press stud and earth point.

Durable 2-layer synthetic rubber bench material is resistant to solder splash and abrasion.

Material is 2mm thick

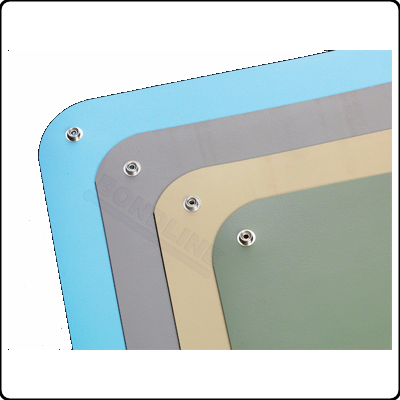

Available in Blue, Grey, Green or Beige.

Lay flat properties

Which ESD Bench Matting do I need

ESD mats are designed to eliminate static on its surface and any objects/ devices placed upon it. For a mat to correctly ground an item, the mat must be conductive or dissipative, if the material is insulative items will not allow charge to drain to ground.

Rubber advantages over Vinyl:

Rubber is heat resistant (resistant of hot solder where Vinyl material will melt.)

Rubber remains in it’s same form, where vinyl can change and become harder in cold conditions.

Rubber is said to be better for the environment.

Rubber is stable, ESD properties cannot change.

Rubber is generally cheaper to manufacture, cost effective savings!

PERFORMANCE

The static matting is based on the material it is constructed from, electrical properites, tolerance to heat and chemicals.

Note, dirt can behave as an insulator, it is important to regularly clean the mat before testing / monitoring the resistivity.