Description

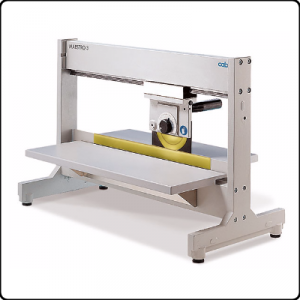

Off-cut remover Hektor 2

Separates milled PCBs carefully and fast

Hektor separates milled PCBs carefully and fast. The offcut material is removed smoothly and precisely. The matrix consists of two parts. This ensures easy and cost-saving change of the blades. Compressed air is used for the separation process.

The operating pressure can be set on the machine. When the foot switch is pressed, the off-cut is punched out. The off-cuts are collected in the collecting box. When the gate is opened the waste material can be extracted.

| Technical Data | Hektor 2 |

|---|---|

| Separation type | Punch blade |

| Operation | by hand |

| PCB thickness | max. 2.5 mm |

| Air connection | 1/4″-plug-in coupler |

| Operating pressure | typical 4 bar |

| Temperature / Humidity Operation Temperatur / Luftfeuchte Storage Temperatur / Luftfeuchte Transport |

+5 – 40° C / 10 – 85 % not condensing +0 – 60° C / 20 – 80 % not condensing -25 – 60° C / 20 – 80 % not condensing |

| Weight | 2.7 kg |

| Dimensions H x W x D | 170 x 220 x 255 mm |

| Approvals | CE, FCC class A |